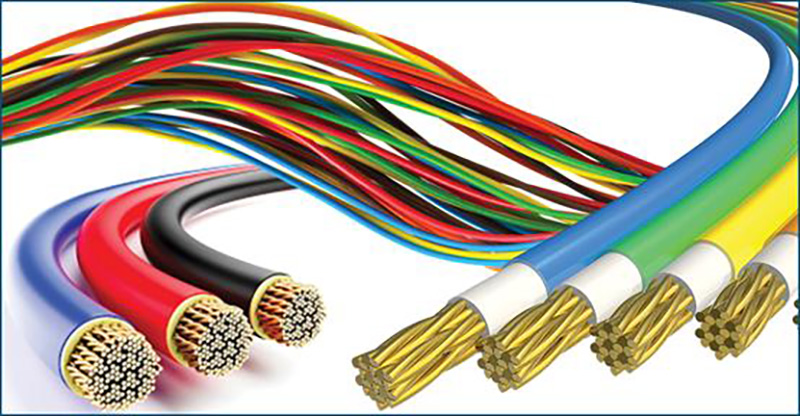

PRZEWÓD

Trend w kierunku bezhalogenowych środków zmniejszających palność o NISKIM dymieniu stawia przed producentami przewodów i kabli nowe wymagania w zakresie przetwarzania.Nowe mieszanki przewodów i kabli są mocno obciążone i mogą powodować problemy z uwalnianiem podczas obróbki, ślinienie się matrycy, słabą jakość powierzchni i dyspersję pigmentu/wypełniacza.Nasze dodatki silikonowe oparte są na różnych żywicach, aby zapewnić optymalną kompatybilność z tworzywem termoplastycznym.Wprowadzenie przedmieszki silikonowej serii SILIKE LYSI znacznie poprawia przepływ materiału, proces wytłaczania, dotyk i odczucie powierzchni poślizgu oraz tworzy efekt synergii z wypełniaczami zmniejszającymi palność.

Są szeroko stosowane w związkach drutowych i kablowych LSZH / HFFR, związkach XLPE łączących silan, drutach TPE, związkach PVC o niskim zadymieniu i niskim COF.Sprawianie, że produkty z drutu i kabli są przyjazne dla środowiska, bezpieczniejsze i mocniejsze w celu uzyskania lepszej wydajności końcowej.

• Druty i kable o niskiej emisji dymu bez halogenów

• Druty i kable ognioodporne bezhalogenowe

• Cechy

Popraw przepływ stopu materiału, zoptymalizuj proces wytłaczania

Zmniejsz moment obrotowy i ślinienie się matrycy, Szybsza prędkość linii wytłaczania

Popraw dyspersję wypełniacza, zmaksymalizuj produktywność

Niższy współczynnik tarcia przy dobrym wykończeniu powierzchni

Dobry efekt synergii z uniepalniaczem

• Mieszanki kablowe usieciowane silanem

• Mieszanka XLPE szczepiona silanem do przewodów i kabli

• Cechy

Popraw przetwarzanie żywicy i jakość powierzchni produktów

Zapobiegaj wstępnemu sieciowaniu żywic podczas procesu wytłaczania

Brak wpływu na końcowe usieciowanie i jego prędkość

Zwiększ gładkość powierzchni, szybszą prędkość linii wytłaczania

Polecaj produkty:LYSI-401, LYPA-208C

•Mieszanki kablowe PVC o niskiej emisji dymu

• Mieszanki kablowe PVC o niskim współczynniku tarcia

• Cechy

Popraw właściwości przetwarzania

Znacznie zmniejszyć współczynnik tarcia

Trwała odporność na ścieranie i zarysowania

Zmniejszenie defektów powierzchni (pęcherzyków podczas wytłaczania)

Zwiększ gładkość powierzchni, szybszą prędkość linii wytłaczania

• Mieszanki kablowe TPU

• Cechy:

Popraw właściwości przetwarzania i gładkość powierzchni

Zmniejsz współczynnik tarcia

Zapewnij kabel TPU o trwałej odporności na zarysowania i ścieranie

Poleć produkt:LYSI-409